Description

1. Overview of Trap Valve

VTON trap valves are engineered to operate with a lever ball mechanism connected to the valve core. The float adjusts with the condensate level to open and close the valve seamlessly. During startup, an automatic air discharge system efficiently expels non-condensable gases, while the float-driven mechanism regulates continuous condensate discharge.

Applications:

- Industrial steam heating equipment

- Large-scale heat exchangers

- Dryers and jacketed kettles

- High-capacity condensate removal systems

2. Product Features

- Robust Sealing: Precision-built valve mechanism ensures excellent sealing and durability.

- Compact and Efficient: Balanced double-seat design offers a smaller footprint with larger discharge capacity, ideal for high-demand applications.

- Air Venting System: Built-in bimetallic air discharge valve prevents air blockages and steam locking.

- Rapid Start-Up: Unique U-shaped bimetal air vent significantly reduces equipment start-up time.

- Ease of Maintenance: All components are mounted on the valve cover, allowing for easy maintenance without removing the valve from the pipeline.

- High Discharge Capacity: Capable of handling large condensate volumes across the entire working pressure range without adjustment or replacement of internal components.

3. Technical Specifications

- Maximum Discharge Capacity: Up to 100 tons/hour

- Working Pressure: Adjustable for high-pressure systems

- Temperature Range: 0℃ to steam temperature

- Construction Material: High-durability materials suitable for steam environments

- Maintenance: Designed for on-site servicing without pipeline removal

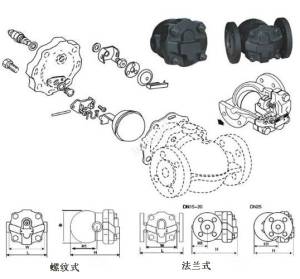

4. Product Diagram