Description

1. Overview of Industrial Strainer

Industrial strainers are vital pipeline components used to filter out impurities and protect valves and equipment downstream. Typically installed at the inlet of devices such as pressure-reducing valves, relief valves, and water level regulators, these strainers prevent clogging and ensure smooth operation.

Applications:

- Water, oil, and gas pipelines

- Industrial systems requiring impurity filtration

- Protection of downstream equipment such as valves and regulators

Features:

- Compact design with advanced structure for minimal resistance

- Easy-to-clean detachable filter cartridge

- Durable stainless steel internal components for long-term reliability

2. Technical Parameters

- Body Material: Stainless steel, carbon steel, brass

- Nominal Diameter: DN15 ~ DN500

- Filter Frame and Mesh Material: Stainless steel

- Seal Material: Oil-resistant asbestos, nitrile rubber (NBR), PTFE

- Working Temperature: -80℃ ~ 450℃

- Nominal Pressure: 1.6 ~ 10 MPa (150Lb ~ 600Lb)

- Filtration Precision: 10 ~ 300 mesh/inch

- Manufacturing Standard: VTON

3. Product Features

- Advanced Structure: Compact and durable design with minimal resistance, ensuring high filtration efficiency.

- Versatile Media Compatibility: Suitable for water, oil, and gas filtration with customizable mesh sizes to meet user requirements.

- Easy Maintenance: Detachable filter cartridge allows quick cleaning and reinstallation, reducing downtime.

- Robust Construction: Internal stainless steel components ensure durability and resistance to wear.

- Cost-Effective Operation: Low resistance and efficient performance minimize operational costs and maintenance time.

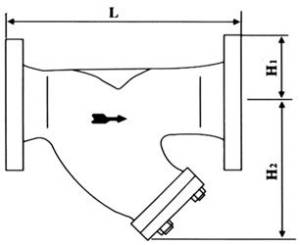

4. Dimensions