Description

1. Overview of Electric Wafer Butterfly Valve

The Electric Wafer Butterfly Valve by VTON combines an angle-stroke electric actuator with a wafer-type soft or hard-sealed butterfly valve. It is driven by an electric actuator for opening and closing, with optional intelligent adjustment for flow rate, pressure, and temperature. This valve is highly versatile and suitable for a wide range of industrial applications.

Key Products:

- Electric Cast Steel Butterfly Valve

- Electric Stainless Steel Butterfly Valve

- Electric Soft-Seal Butterfly Valve

- Electric Hard-Seal Butterfly Valve

2. Features

- Innovative Design: Detachable valve seat design allows for material customization based on media properties, ensuring durability and adaptability to high/low temperature, corrosion, and aging resistance.

- Efficient Operation: The zero-offset design minimizes operating torque, while the rubber-lined structure ensures low friction and extended service life.

- Seamless Sealing: The rubber valve seat features a molded design for balanced support, maintaining zero leakage at full closure.

- Corrosion Resistance: Ductile iron surfaces are coated with high-temperature epoxy resin powder, providing excellent corrosion protection and robust adhesion to the valve body.

3. Technical Parameters

- Nominal Diameter: DN50-DN600

- Nominal Pressure: 1.0-1.6 MPa

- Connection Type: Wafer

- Valve Body Material: HT200, QT400, WCB, Stainless Steel

- Valve Plate Material: QT400, Aluminum Bronze, Nylon 11, Stainless Steel

- Valve Seat: NBR, EPDM

- Actuator Options: AC220V/AC380V/AC110V/DC24V; Electric Control Box

- Applicable Media: Freshwater, seawater, wastewater, air, natural gas, oil, general chemical media

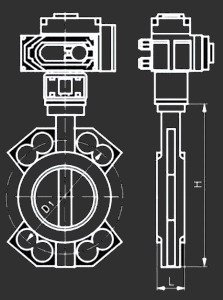

4. External Dimensions

| DN | L | H | 1.0MPa | 1.6MPa | Electric Actuator Options

AC220V/AC380V |

|||||

| D | D1 | n-d | D | D1 | n-d | |||||

| 50 | 42 | 197 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | VTD-05 | VTHQ-05 |

| 65 | 44 | 217 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | VTD-05 | VTHQ-05 |

| 80 | 44 | 232 | 200 | 160 | 8-18 | 200 | 160 | 8-18 | VTD-05 | VTHQ-05 |

| 100 | 50 | 266 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | VTD-08 | VTHQ-08 |

| 125 | 56 | 293 | 250 | 210 | 8-18 | 250 | 210 | 8-18 | VTD-10 | VTHQ-10 |

| 150 | 56 | 319 | 285 | 240 | 8-23 | 285 | 240 | 8-23 | VTD-20 | VTHQ-20 |

| 200 | 60 | 389 | 340 | 295 | 8-23 | 340 | 295 | 12-23 | VTD-40 | VTHQ-50 |

| 250 | 68 | 456 | 395 | 350 | 12-23 | 405 | 355 | 12-28 | VTD-60 | VTHQ-60 |

| 300 | 78 | 520 | 445 | 400 | 12-23 | 460 | 410 | 12-28 | VTD-80 | VTHQ-80 |

| 350 | 78 | 587 | 505 | 460 | 16-23 | 520 | 470 | 16-28 | VTD-100 | VTHQ-120 |

| 400 | 102 | 649 | 565 | 515 | 16-28 | 580 | 525 | 16-31 | VTD-200 | VTHQ-200 |

| 450 | 114 | 713 | 615 | 565 | 20-28 | 640 | 585 | 20-31 | VTD-300 | VTHQ-300 |

| 500 | 127 | 786 | 670 | 620 | 20-28 | 715 | 650 | 20-34 | VTD-400 | VTHQ-400 |