Description

1. Overview of Swing Check Valve

Swing check valves utilize an internal rocker arm swing mechanism to control fluid flow and prevent backflow. The valve disc swings freely to allow forward flow and closes automatically when the flow reverses. These valves are suitable for cleaning media, including water, steam, and oil, but are not recommended for media containing solid particles or high viscosity.

Applications:

- Water systems

- Steam and oil pipelines

- Chemical and petrochemical industries

- Power generation and metallurgical processes

2. Technical Parameters

- Size: DN15-3000 (1/4″ – 100″)

- Pressure: PN0.6-PN320; Class150LB-2500LB; JIS10K-20K

- Temperature Range: -196℃ ~ 550℃

- Body Material: Cast iron, ductile iron, cast steel, stainless steel, chromium-molybdenum steel

- Sealing Surface: Hardfaced chromium stainless steel, hard alloy, chromium-nickel-titanium stainless steel

- Gaskets: Spiral wound steel-graphite, PTFE

- Connection Types: Flange, threaded, welded

- Working Media: Water, steam, oil, nitric acid, acetic acid, oxidizing media, and urea

3. Product Features

- Leak-Free Design: Internal rocker arm swing structure ensures all opening and closing components are housed within the valve body, with no external leakage points aside from the middle flange sealed with gaskets and rings.

- Flexible Arm Connection: The rocker arm and valve disc are connected with a spherical structure, providing freedom of movement within 360 degrees and allowing for slight positional compensation.

- Durable Sealing: The sealing surfaces of the valve disc and seat are made with iron-based or Stellite cobalt-based hard alloys, offering excellent resistance to wear, high temperatures, corrosion, and scratches for a longer service life.

- Media Compatibility: Best suited for clean media and not recommended for use with solid particles or highly viscous substances.

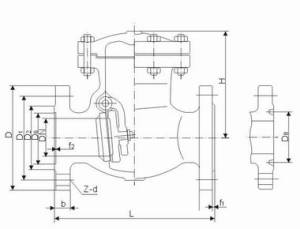

4. Product Diagram