Description

1. Overview of Lift Check Valve

Lift check valves are automatic valves designed to prevent backflow by utilizing the fluid pressure difference and the valve disc’s weight for lifting and lowering. These valves are suitable for most horizontal pipelines, ensuring protection of upstream equipment. Their advantages include a simple structure, reliable operation, and convenient maintenance.

Applications:

- Horizontal pipelines in tanks

- Purification equipment

- Petrochemical, chemical, and metallurgical industries

- Power generation and light textile production

2. Technical Parameters

- Size: DN15-DN3000 (1/4″ – 100″)

- Pressure: PN0.6-PN320; Class150LB-2500LB; JIS10K-20K

- Temperature: -196℃ ~ 550℃

- Body Material: Cast iron, ductile iron, cast steel, stainless steel, chromium-molybdenum steel

- Sealing Surface: Hardfaced chromium stainless steel, hard alloy, chromium-nickel-titanium stainless steel

- Gaskets: Spiral wound steel-graphite, PTFE

- Connection Types: Flange, threaded, welded

- Working Media: Water, steam, oil

3. Product Features

- Automatic Operation: The valve disc lifts and lowers based on fluid pressure, ensuring smooth operation and backflow prevention.

- Wide Media Compatibility: Suitable for water, steam, and oil pipelines across diverse industries.

- Durable Construction: Made from high-quality materials, including cast steel and stainless steel, with robust sealing surfaces for extended service life.

- Flexible Installation Options: Available in flange, threaded, and welded connections to meet various pipeline requirements.

- High Pressure and Temperature Tolerance: Designed to perform reliably under extreme conditions, withstanding pressures up to 320MPa and temperatures up to 550℃.

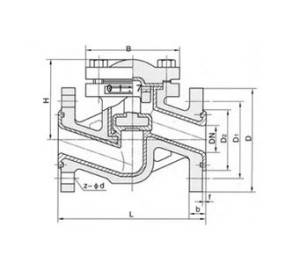

4. Product Diagram