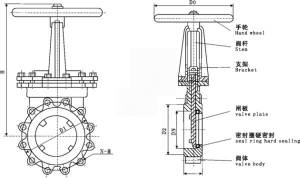

Description

1. Overview of Knife Gate Valve

Knife gate valves, also known as knife-shaped gate valves, are specifically designed for demanding industrial applications. With a stainless steel body and blade, the valve ensures reliable sealing by scraping off debris and preventing material buildup. These valves are ideal for industries such as papermaking, wastewater treatment, and bulk material transportation.

Applications:

- Papermaking and pulp industries

- Industrial and urban wastewater treatment

- Chemical plants, fly ash handling, and food processing

2. Product Features

- Compact Design: Occupies minimal space, lightweight, easy to install, with wear-resistant and anti-blocking measures for long service life.

- Flushing Ports: Multiple ports for air, steam, or water flushing prevent sediment buildup, suitable for challenging fluids.

- Wear-Resistant Cone: The inlet end features a wear-resistant cone made from polyester or Ni-based cast iron to protect seals from particle erosion.

- PTFE Scraper: Prevents abrasive particles such as dust and gravel from entering the packing box.

- Circular Channel Design: The fully circular channel and blade-shaped bottom enhance smoothness and sealing performance.

3. Main Component Materials

- Body: Stainless steel

- Cover: Stainless steel

- Gate Plate: Stainless steel

- Stem: Stainless steel

- Sealing Ring: Rubber, PTFE, stainless steel, or hard alloy

- Manufacturing Standard: VTON

4. Technical Parameters

- Nominal Pressure: PN0.6-2.5MPa

- Shell Test Pressure: 1.5xPN

- Sealing Test Pressure: 1.1xPN

- Working Temperature:

- Rubber ≤80℃

- PTFE Seal ≤180℃

- Hard Seal ≤425℃

- Applicable Media: Syrup, pulp, sewage, coal slurry, ash-water mixtures

- Drive Modes: Manual, pneumatic, electric

- Nominal Diameter: DN3-1000mm

- Protection Level: IP65, IP67, IP68

5. Dimensions