Description

1. Overview of Steam Globe Valve

The steam globe valve is specifically designed for installation on steam pipelines to control the flow of steam. Made with stainless steel or titanium alloy bellows as the valve stem sealing element, these valves prevent steam leakage and ensure optimal performance in high-temperature environments.

Applications:

Widely used in food processing, pharmaceuticals, petroleum, chemicals, natural gas, steel, environmental protection, and papermaking. They are also suitable for boilers, municipal systems, and everyday industrial needs.

2. Technical Parameters

- Connection Types: Flange, welded, threaded

- Actuation: Manual (DN15-DN1000)

- Working Pressure: PN1.6 ~ PN16MPa, 150LB ~ 1500LB

- Working Temperature: -60℃ ~ 550℃

- Media: Water, oil, steam, and other fluids

- Body Materials: Carbon steel, stainless steel, alloy steel

- Packing: Flexible graphite, PTFE

- Stem Material: Chrome stainless steel Cr13, stainless steel

- Body Finish:

- Cast steel: Matte violet-blue

- Stainless steel: Natural finish (effective rust prevention)

3. Product Features

- Simple structure, easy to manufacture and maintain.

- Small working stroke and quick opening/closing time.

- Excellent sealing performance, low friction between sealing surfaces, and long service life.

- Valve stem does not contact the medium at high temperatures, ensuring zero leakage.

- High strength and toughness, capable of tens of thousands of opening and closing cycles.

- Ergonomic handwheel design for effortless operation and extended durability.

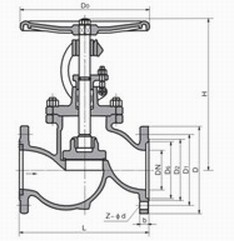

4. Product Diagram